TURNOUT MATERIAL SELECTION GUIDE

Every turnout composite system is made up of an outer shell, moisture barrier, and thermal liner. Taking the time to understand the importance of each layer and its benefits, is key to keeping your crew safe.

COMPOSITE SYSTEMS

Before choosing which turnout materials make up the right combination for your department's safety, you need to understand how they work together as a composite system.

What is a composite system? All fire suits are made up of 3 layers; the outer shell, moisture barrier, and thermal liner. When talking about these 3 fabrics together, we refer to them as a composite system. It is not possible to build safe gear that meets all NFPA requirements without one of these layers. Therefore, it is extremely important that each layer works well together to provide balanced protection.

Composite systems determine:

-

How much the overall turnout gear will weigh

-

How easily your body will be able to self regulate back to a normal temperature

-

How much heat your turnout gear will endure while protecting you

-

How much strength it'll take for an object to penetrate through the protective layers

-

How easily you'll be able to move through a fire scene

Deciding on the right composite system for your fire department begins with determining your needs, then finding a suitable balance.

OUTER SHELL

What is an outer shell? The outer shell is the outer most layer of the composite system. It is the layer that displays your patches, reflective materials and pockets.

What is the Importance of an outer shell? The main functions of the outer shell include:

-

Resistance To Flame

-

First Defense Against Abrasions & Tearing

-

Contributes to the overall weight of the garment

-

Impacts flexibility and breathability

No intentionally added PFAS.

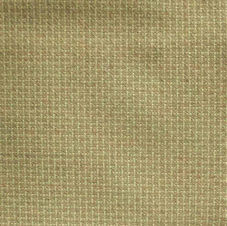

TECGEN51® FABRIC

Flame-resistant, twill weave, patented material built from a combination of high-density TECGEN fibers and para-aramids offers superior TPP, RPP, and breathability. Made with no intentionally added PFAS.

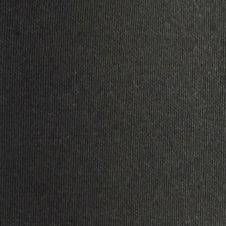

ARMOR™ AP

Lightweight, flexible and strong. Content - 80% NOMEX®/KEVLAR® (40/60) blend spun yarn with 20% KEVLAR® filament yarn. Material Weight - 6.5oz/yd2. Twill weave. Made with Safety Components PF Zero™ Finish.

AGILITY™

A new fabric offering ease of movement with TenCate Enforce Technology. KEVLAR® / NOMEX® / PBO blend. Material Weight - 6.6 oz/yd2. Twill weave. Made with TenCate FreeFAS Finish.

GENTEX® Dual Mirror® Aluminized Fabric

Aluminized PBI®/ Para-Aramid is a fabric blend that combines polybenzimidazole synthetic fiber with para-aramid to create a high-performing fabric. Material Weight - 7.0 oz/sq yd. Ripstop Knit.

FLEX7™

Light yet strong, greater ease of movement and more flexibility. Content - 70% PBI® /KEVLAR® blend spun yarn with 30% KEVLAR® filament yarn. Material Weight - 6.9oz/yd2. Twill weave. Made with TenCate FreeFAS Finish.

PBI MAX® LP

Lighter, stronger, with enhanced break open protection. Content - 70% PBI® LP/Para-Aramid spun yarns with 30% KEVLAR® filament yarn. Material Weight - 6.0oz/yd2. Twill weave. Made with Safety Components PF Zero™ Finish.

Synergy NOMEX®

Proven Economical Protection. Content - 93% NOMEX®, 5% KEVLAR®, 2% Anti-Static blend spun yarn. Material Weight - 7.5 oz/yd2. Plain weave.

HORIZON™

Turnout outer shell material designed to maintain tear strength and color fastness, even after multiple washings. Made without intentionally added PFAS, this RipTwill material weighs 6.8 oz/yd2.

PBI MAX® 7OZ

Extremely flexible, lighter weight, and strong. Content - 70% PBI®/ KEVLAR® blend spun yarn with 30% KEVLAR® filament yarn. Material Weight - 7.0oz/yd2. Twill weave. Made with Safety Components PF Zero™ Finish.

PIONEER™

A new, innovative, lightweight twill weave with TenCate Enforce Technology. Content - KEVLAR®/ NOMEX®. Material Weight - 6.6 oz/yd2. Twill weave. Made with TenCate FreeFAS Finish.

MOISTURE BARRIERS

The moisture barrier is the layer of protection found in the middle of the composite system. Although hidden from sight, the moisture barrier contributes to the following turnout properties:

-

Chemical, Liquid, & Bloodborne Pathogen Resistance

-

Insulation & Thermal Protection

-

Overall Weight Of The Garment

-

Flexibility & Breathability

THERMAL LINERS

The thermal liner is the innermost layer of the turnout gear's composite system. It is the layer you see inside the coat as you pull it on. The thermal liner plays an important role in:

-

Moisture Wicking (Removing Sweat Away From The Body)

-

Breathability (Allowing Heat To Leave The Body & Have Somewhere To Go)

-

Overall Weight Of The Garment

-

Flexibility

REFLECTIVE TRIM OPTIONS

Enhance your PPE game with our durable trim options! Not only will this variety of trim provide you with high visibility when on scene, but also increased protection to meet the extensive demands of your job.

3M™ Scotchlite™ Reflective Comfort Trim

Made to be extremely light and breathable, this trim provides excellent reflectivity in low light and nighttime conditions to help keep you safe. The exposed reflective lenses are wide angled while providing flame resistance and heavy duty protection. When you select this trim, you will feel the flexibility with each movement, especially in tight spaces.

Available on the following product lines:

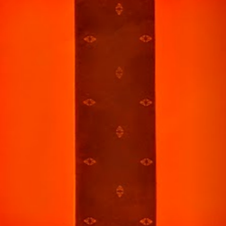

3M™ Scotchlite™ Reflective Triple Trim

Trusted to stand up in extreme heat, this trim maintains its brightness, flexibility, and shape no matter how hot the conditions are! Created to provide exceptional nighttime visibility so you can be seen and stay protected.

Available on the following product lines:

ORALITE® Brilliance

Sew on, fire resistant trim developed for technical rescue, wildland, and industrial gear where reliable visibility makes all the difference.

Available on the following product lines:

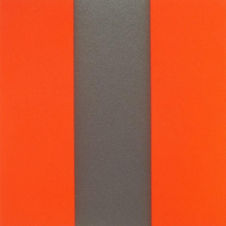

3M™ Scotchlite™ Reflective Solid Trim

Great for overall performance during your calls! The reflective surface of this solid color fluorescent trim is perfect for daytime visibility with reflective properties for nighttime visibility.

Available on the following product lines: